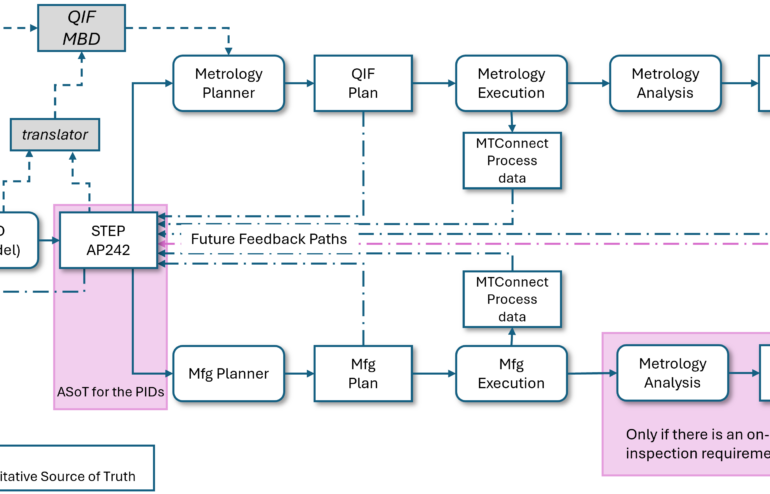

Persistent IDs and Traceability

In the era of Model-Based Definition (MBD), establishing seamless traceability from design intent through manufacturing to quality inspection has become essential. Traditional manufacturing workflows often break the connection between design specifications and inspection results. When a part fails inspection, engineers struggle to trace the failure back to specific design requirements.

This challenge is addressed by implementing Persistent Identifiers (UUIDs) that maintain identity across system boundaries, as documented in the “Recommended Practices for Cross-Domain Exchange for Downstream Uses“, jointly published by DMSC and the CAx-IF.

The STEP standard uses V5_UUID_ATTRIBUTE (namespace-based, repeatable UUIDs) to tag geometric entities and PMI elements. QIF files preserve these identities through EntityExternalIds, creating a robust linkage mechanism that survives data translation between CAD, CAM, and CMM systems.

Research validated by CAx-IF testing demonstrated that Persistent ID-based traceability between STEP and QIF is achievable and practical. The combination of V5_UUID_ATTRIBUTE in STEP files and EntityExternalIds in QIF provides a robust, standards-compliant mechanism for maintaining the digital thread from design through inspection. With proper implementation following established rules and patterns, 100% traceability success is attainable, enabling true Model-Based Definition workflows where design intent flows seamlessly to quality verification.